Add to Cart

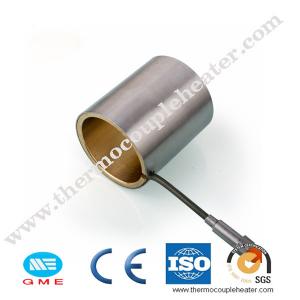

Hot Runner nozzle Heater For Injection Moulding Machine,Cast Coil Heaters heating elements

Description:

1) Nozzle coil Heater is a tube-shapedindustrial heating element (electrical resistance), which is widely used in the process heating industry, usually custom manufactured to a specific watt density, based on its intended application.

2) There are various kinds of enamel tubular heater, U shape, W shape, double end, etc. Our enamel tubular heaters are customized according to your specifications.

Specification:

---Specializes in manufacturing heater,thermocouple and heating equipment more than 8 years

---Up to 200000 units turned out each month

---Custom orders welcome

---USA high purityMgo,Germany Nici8020 alloy wire,Germany fiberglass protection

---R&D team updates every month with 10 new items.

Oder Detail

---Model Number

---Voltage&Power

---Dimension for cross section

---Inner and length for coil heater

---Length of sheath

Application:

1. Injection moulding machine nozzle

2. Hot Runner Nozzles & Bushings

3. Packaging machineries

4. Hot runner Injection moulds.

5. Injection & Blow Moulding Machine Nozzles.

6. PET prefrom & Thin wall container Moulds

7. Hot runner Manifolds.